With the growing recognition of hydrogen's capacity as a clean, scalable, and renewable energy source, there are questions within the market regarding the most effective approach to transporting and storing the hydrogen required for various applications. Choosing between delivering hydrogen as a liquid or a gas is a big decision. To make the right choice, you need to consider factors like scalability, efficiency, environmental impact, and safety.

In this article, we delve into the advantages of gaseous hydrogen delivery, shedding light on its application, future prospects and scalability. We'll explore where this method can be useful and how it plays a key role in creating a more environmentally friendly and efficient energy landscape.

Gaseous Hydrogen's Distinctive Advantages

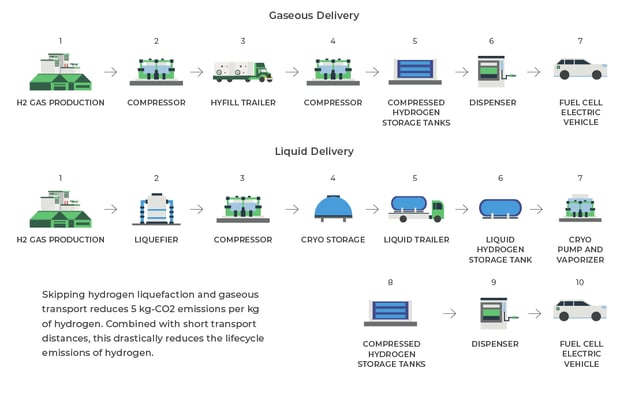

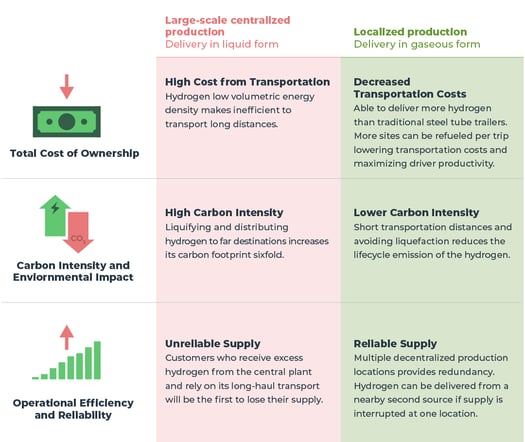

When fleet operators weigh the options for hydrogen delivery, they face a decisive choice between two primary alternatives: liquid hydrogen and gaseous hydrogen. Liquid hydrogen stands out as the preferred method for long-distance transport due to its higher energy density. However, it does pose significant challenges such as elevated costs, necessitating complex cold storage infrastructure and insulation to mitigate evaporation risks. The energy-intensive process of liquefaction further contributes to its carbon footprint. These factors collectively escalate expenses and reliability concerns, especially for long-haul transport. On the other hand, gaseous hydrogen proves to be more suitable for short-haul delivery, simplifying infrastructure requirements. This makes it particularly attractive for newcomers in the hydrogen market who seek to avoid substantial investments in cryogenic storage and vaporizers. Additionally, utilizing gaseous hydrogen reduces the risk of boil-off associated with liquid deliveries, presenting a more manageable solution for local delivery scenarios.

>>Read more about Fact vs. Fiction: Debunking Common Myths Surrounding Hydrogen

On the other hand, gaseous hydrogen provides a more efficient option. Using high-pressure hydrogen transport trailers, avoids the complexities of cryogenic storage and insulation. Gaseous hydrogen can be compressed and stored in high-pressure tanks, which are easier to manage. This approach is even more beneficial with local production and delivery, especially through strategically positioned hubs like Bayotech's. These hubs improve supply availability and efficiency, offering fleet operators a reliable solution to optimize their hydrogen supply chain.

>>Read more about hydrogen delivery in our new white paper about fueling the future of mobility

Conventional Applications of Gaseous Hydrogen

Gaseous hydrogen finds its place in a range of applications that showcase its adaptability and potential for immediate impact.

Short Distances and Local Distribution:

Gaseous hydrogen excels when it comes to short supply chains, making it an ideal fit for local distribution. By skipping the liquefaction step and favoring shorter transportation distances, the overall emissions tied to hydrogen's lifecycle significantly decrease. This strategic approach results in a smaller carbon footprint, aligning well with sustainability targets.

Rapid Deployment of Infrastructure:

A major advantage of gaseous hydrogen is its low infrastructure demands, leading to reduced ownership costs. Compact high-pressure hydrogen transport trailers and storage modules need little space and can be easily relocated as needed. In contrast, storing cryogenic solutions is both inefficient and costly. Liquid storage requires substantial space, often three times the area of standard gasoline tanks. This space is essential for housing chemicals and on-site conversion processes.

Direct Fueling for Vehicles:

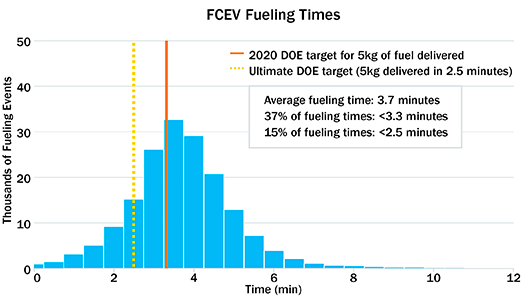

One of the key benefits of using a compressed hydrogen gas storage system is its ability to enable quick vehicle refueling. With a high-pressure gas storage system, refueling takes just minutes, a major improvement compared to the ongoing protocols and processes linked with liquid storage refueling. Refueling processes also incorporate safety features to maintain precise control over hydrogen delivery and promptly detect any irregularities.

Stationary and Backup Power Systems:

Gaseous hydrogen's adaptability extends to stationary power systems, providing uninterrupted energy supply and serving as a reliable backup power source for critical infrastructure.Fuel cell backup systems are the only emissions-free solution that requirements for securing critical infrastructure. Hydrogen fuel cells produce no harmful gases, eliminating the need to handle and store hazardous substances like diesel fuel. They are a sustainable power source, emitting only heat and water as byproducts. BayoTech further enhances the convenience of fuel cell backup systems with on-site refueling solutions, even in remote areas, through our lightweight and towable GTM trailer.

Scaling Up Demo Projects

Scalability of Infrastructure

The advantage of gaseous hydrogen lies in its decentralized production approach, offering redundancy through multiple production locations. This redundancy ensures that hydrogen can be swiftly delivered from a nearby secondary source if the supply is interrupted at one location, minimizing downtime and ensuring continuity. In contrast, liquid hydrogen can lead to supply reliability issues, particularly for customers relying on long-haul transport from central plants, making them vulnerable to supply interruptions.

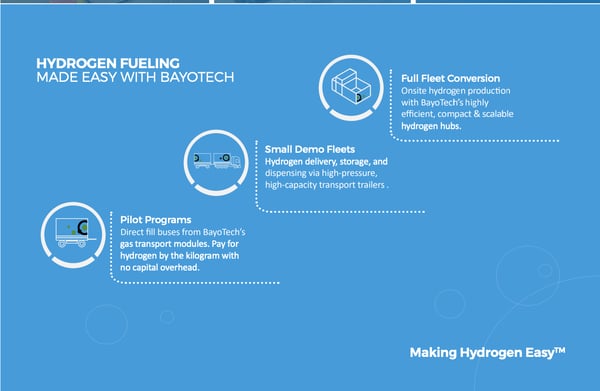

BayoTech's hydrogen hubs take this adaptability to the next level. By installing, owning, and operating hydrogen production facilities near depots, they enable short-distance delivery, significantly reducing infrastructure demands at the fleet owner's site. This approach eliminates concerns about outdated equipment and minimizes associated risks.

Operational ease and low risk are key aspects of BayoTech's approach. We assume responsibility for designing, installing, maintaining, and operating hydrogen generation equipment, leveraging their specialized expertise to handle production, storage, and distribution processes efficiently. Notably, these hubs are constructed in a factory setting on skids, an innovative method that speeds up deployment compared to traditional construction methods.

Demo Projects

By reducing entry barriers for proof-of-concept endeavors, gaseous hydrogen encourages innovation and testing. Notable initiatives like the Champaign-Urbana Mass Transit District (CUMTD) project is a great example of gaseous hydrogen's suitability for pilot projects.

When it became clear that the hydrogen station wouldn't be ready when the buses arrived, CUMTD needed a temporary way to fuel them with hydrogen. To fill this gap and ensure on-time fueling, they turned to BayoTech. Our solution allowed them to transport a lot of compressed gas in a space that's only a third of the size of regular steel-tube trailers. This compact setup meant that CUMTD could efficiently fuel their new buses for test drives without slowing down the progress of their hydrogen production station's development.

Conclusion

Both gaseous and liquid forms hold advantages and drawbacks. Yet, gaseous hydrogen emerges as a highly versatile choice, marked by its immediate impact in short supply chains, rapid infrastructure setup, and direct vehicle refueling. The success of projects like the Champaign-Urbana Mass Transit District initiative underscores its real-world viability.

Furthermore, gaseous hydrogen's scalability and integration into existing infrastructure position it as a key player in the drive towards greener energy solutions. The innovative model of Bayotech's hydrogen hubs exemplifies the efficiency of this approach.